JPEPH

- Commodity name: JPEPH

- Product Description

-

Product Overview

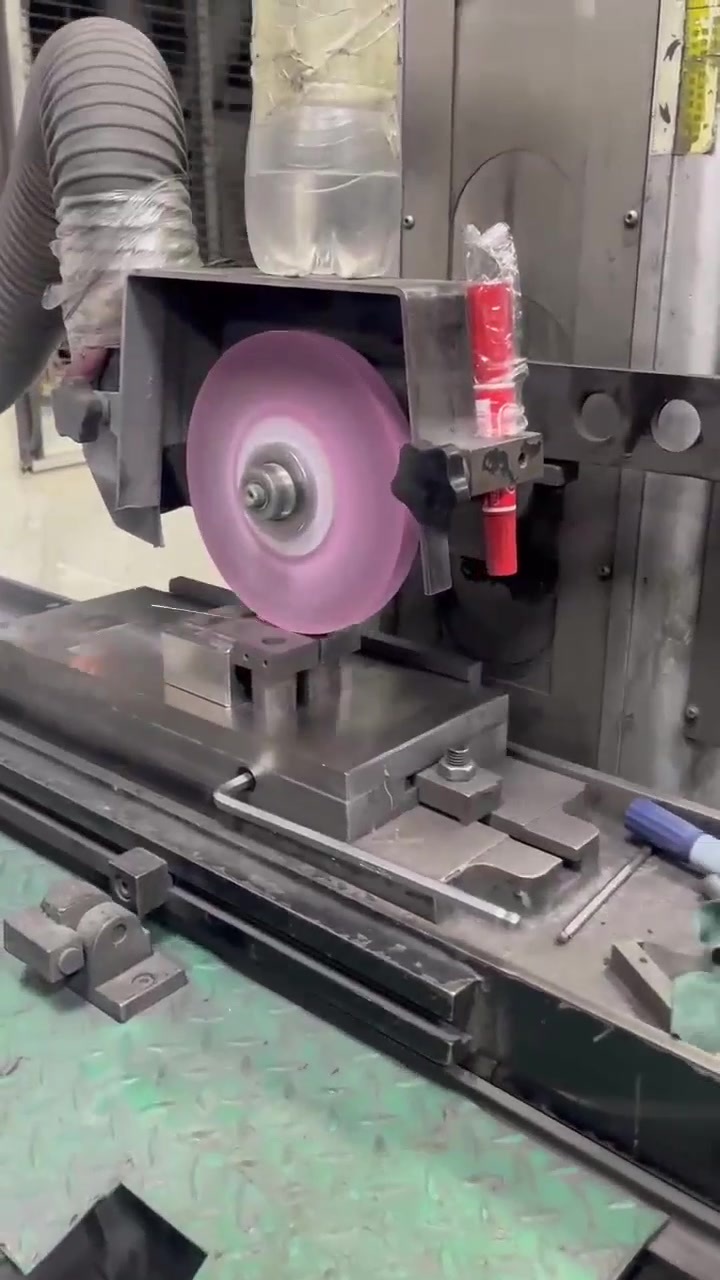

Thimble failure is the number one killer of mold shutdown-- 0. 1 mm of bending can result in millions of scrap losses. Our aerospace grade thimbles are coated with deep ion nitriding and DLC diamond to withstand 800℃ die cast melt and glass fiber scour ≤ 0.003mm deformation. Through millions of impact tests, it provides uncompromised ejection reliability for automotive, medical and optical parts.

Product Features

1. Military-grade precision, never deformed

- μ Level true circle control: Swiss CNC cylindrical grinding, diameter tolerance ± 0.002mm(ISO h level 5)

2. Extreme Surface Technology

- DLC diamond coating: hardness ≥ 3500HV, friction coefficient < 0.1 (60% lower than titanium plating)

3. Global standardization ready-to-wear

- All systems compatible: Supported DME/ HASCO/ FUTABA/ MISUMI standard (Φ 1~Φ 25mm)Product Application Scenario

1. Thin-wall medical parts: Insulin pen holder anti-top white thimble (Φ 0.8mm)

2. Optical lens: PC lamp mirror trackless ejection system

3. Large die-casting: new energy battery pack deep cavity thimble (L=1200mm)

4. Precision electronics: connector insert anti-bending ejector pin

Key words:

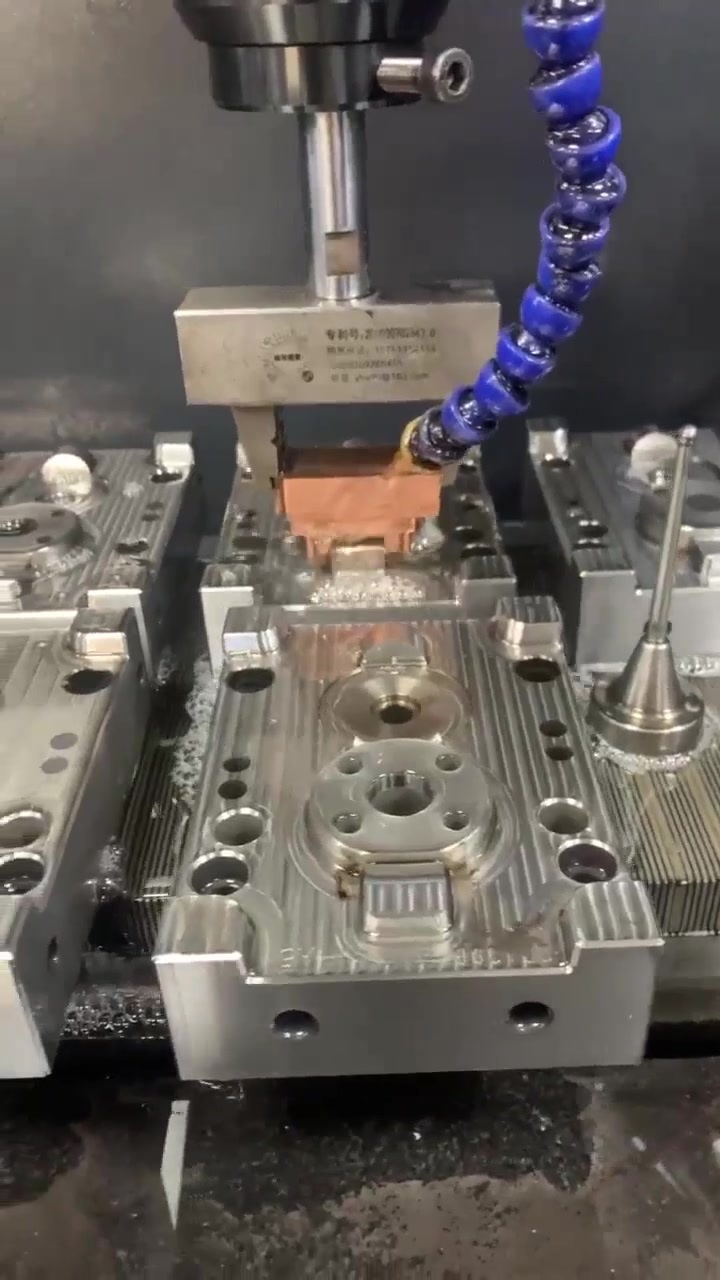

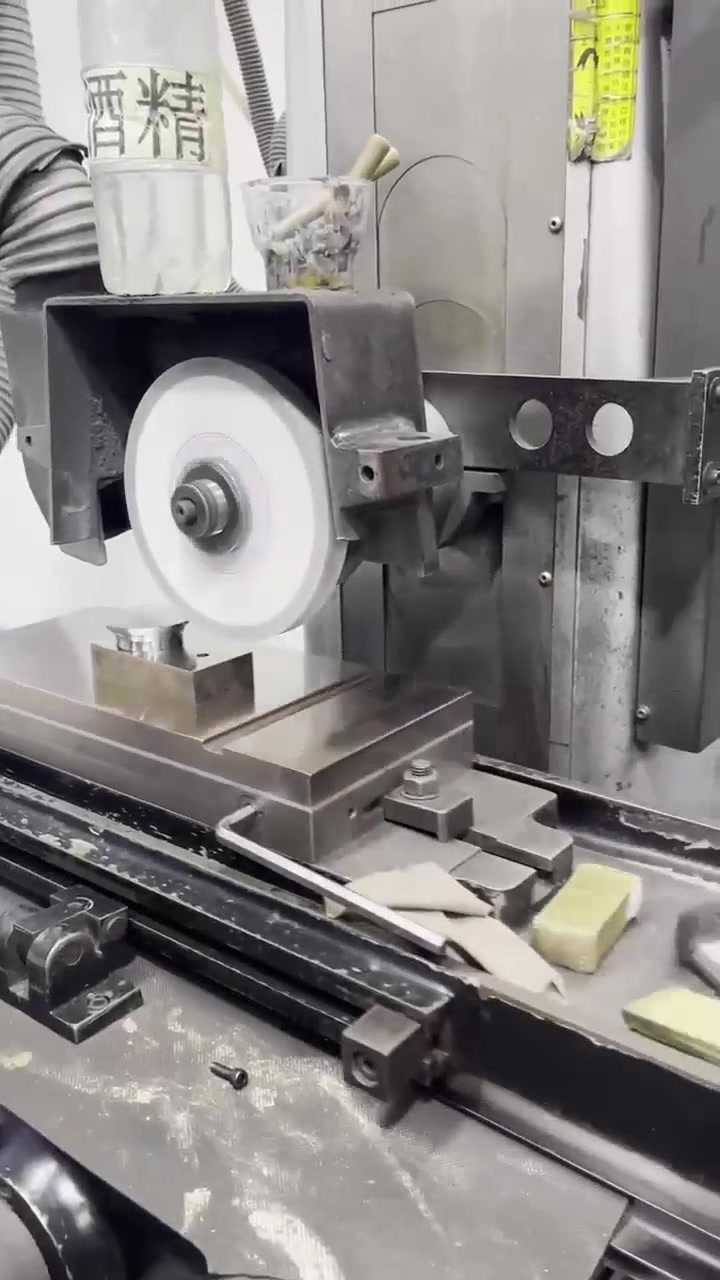

Video display

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

1

2

3

4

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.