JPESS

- Commodity name: JPESS

- Product Description

-

Product Overview

In the deep cavity mold of automobile structural parts and medical devices, 0.01mm support deformation will cause the product scrap rate to increase by 30%. Our multistage composite pins utilize rocket motor material technology, it is still maintained under 1200T clamping force ≤ 0.003mm elastic deformation. 100 000 ultimate pressure tests to provide rigid support for deep ribbed, elongated inserts that never bend.

Product Features

1. Space-grade compression system- Sandwich structure:

① Surface layer: ZrO ₂ ceramic coating (temperature resistance 1600℃)

② Intermediate layer: Tungsten carbide cemented carbide (compressive 2000MPa)

③ Core: Toughy molybdenum alloy (300% improvement in impact toughness)

2. Adaptive pressure distribution

- Spherical microconvex technique: R 0.5 mm spherical crown dispersion stress, contact pressure <300MPa

- Step relief groove: multi-stage annular groove absorbs impact energy and eliminates stress concentration

3. Global standardization ready-to-wear

- All systems compatible: Supported DME GS Series, HASCO ZS specifications, FUTABA S type (Φ 3~Φ 50mm)Product Application Scenario

1. Automobile deep cavity parts: new energy battery box reinforcement rib support (compression resistance 1200T)

2 Medical Implants: Knee Joint Replacement Mold Micro Hosting Needle (Φ 1.5mm)

3. Precision gear: planetary gear module anti-eccentric support system

4. Large die-casting: anti-deformation strut of integrated body frame

Key words:

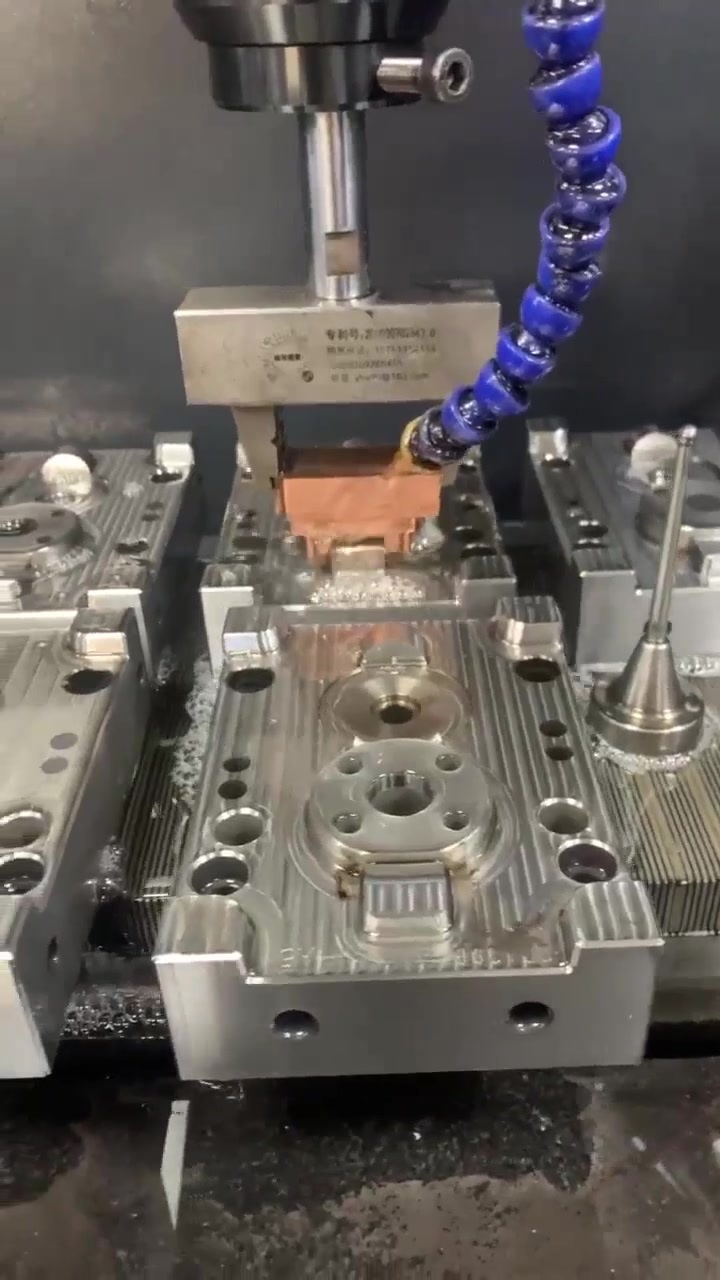

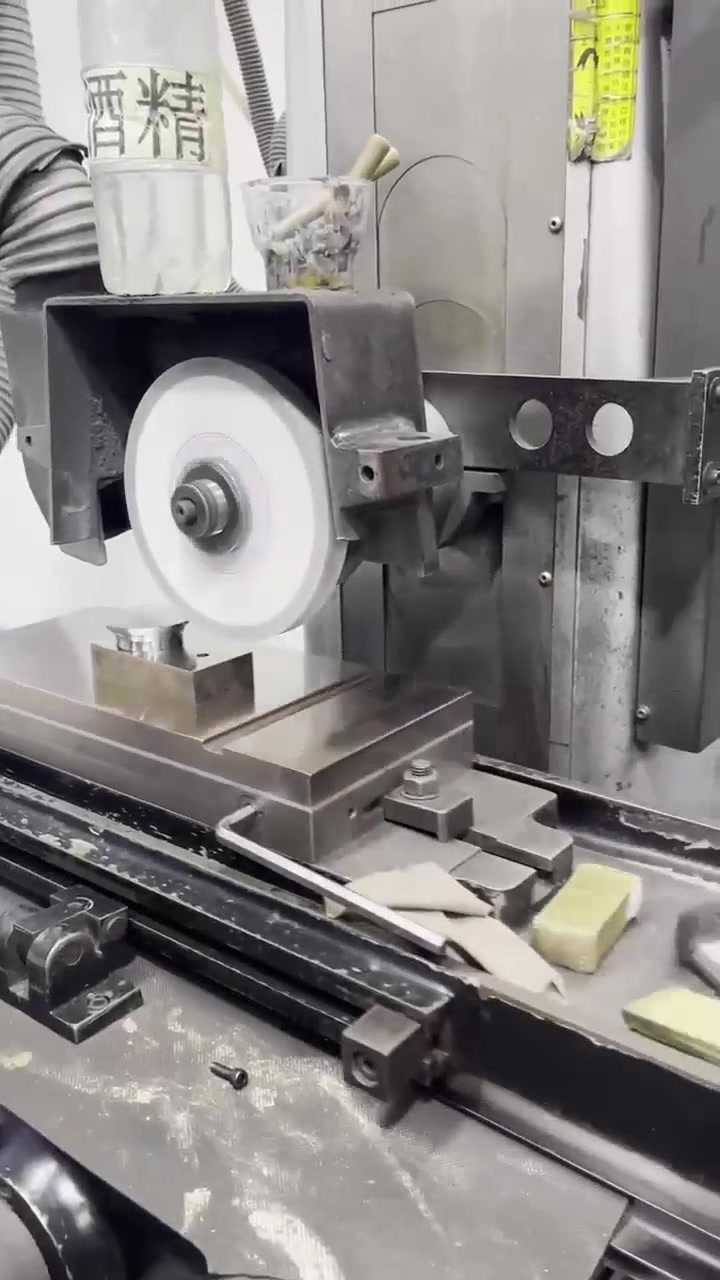

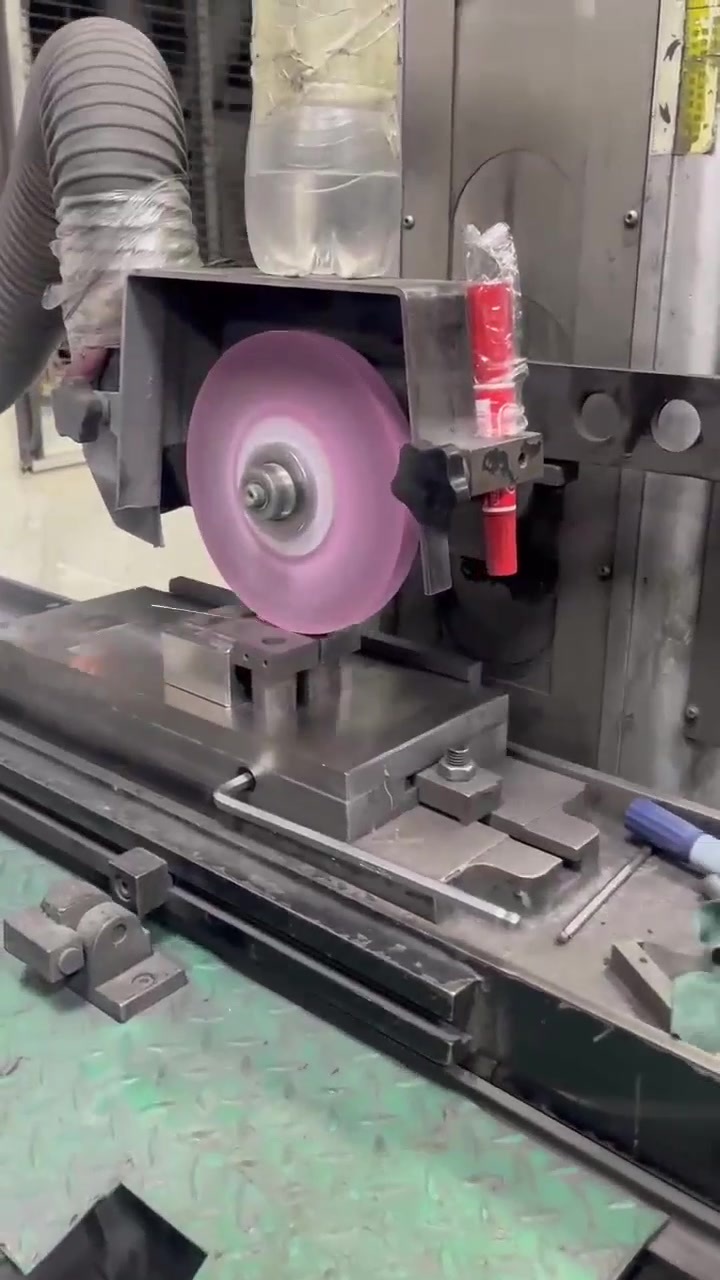

Video display

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

1

2

3

4

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.