JPAJV

- Commodity name: JPAJV

- Product Description

-

Product Overview

When a conventional thimble is injected into a mirror PC, medical catheter, or metal powder injection molding (MIM) when scratches are left on the parts, the air top becomes a hard need for high demoulding requirements. Our Titanium Nitride Coated Gas Ceiling Sleeves achieve contactless ejection with ≤ 0.003mm extreme concentricity and a self-lubricating microporous structure. It is applicable to medical parts and automotive optical parts with the accuracy of 0.01 mm, and the product yield is improved to 99.9%.

Product Features

1. Zero contact ejection to protect the product surface

- Membrane suspension technology: 0. 5 MPa compressed air formation 10 μ m suspension layer, isolating sleeve from workpiece

2. Military grade precision, never deformation

- Two-stage hardening process: SKD 11 Substrate quenching (HRC62°) → cryogenic treatment → PVD coating (2000HV hardness)

3. Out-of-the-box standardization

- Global mold base compatibility: supports the DME family 1/2、HASCO Z series, FUTABA E type standard size

4.Body and valves are manufactured completely from stainless steel, Excellent rust resistance.

5.An effective method of release the vacuum created during plastic injection molding.

6.To substitute ejector pins or other ejector parts for diemouldProduct Application Scenario

1. Optical parts: lamp lens, mobile phone light guide plate without trace ejection

2. Medical parts: zero-pollution demoulding of catheter connector and transparent infusion set

3. Precision electronics: connector insert and micro gear are ejected without damage

4. Surface Finishes: IMD/IML anti-scratch of diaphragm and electroplated parts

Key words:

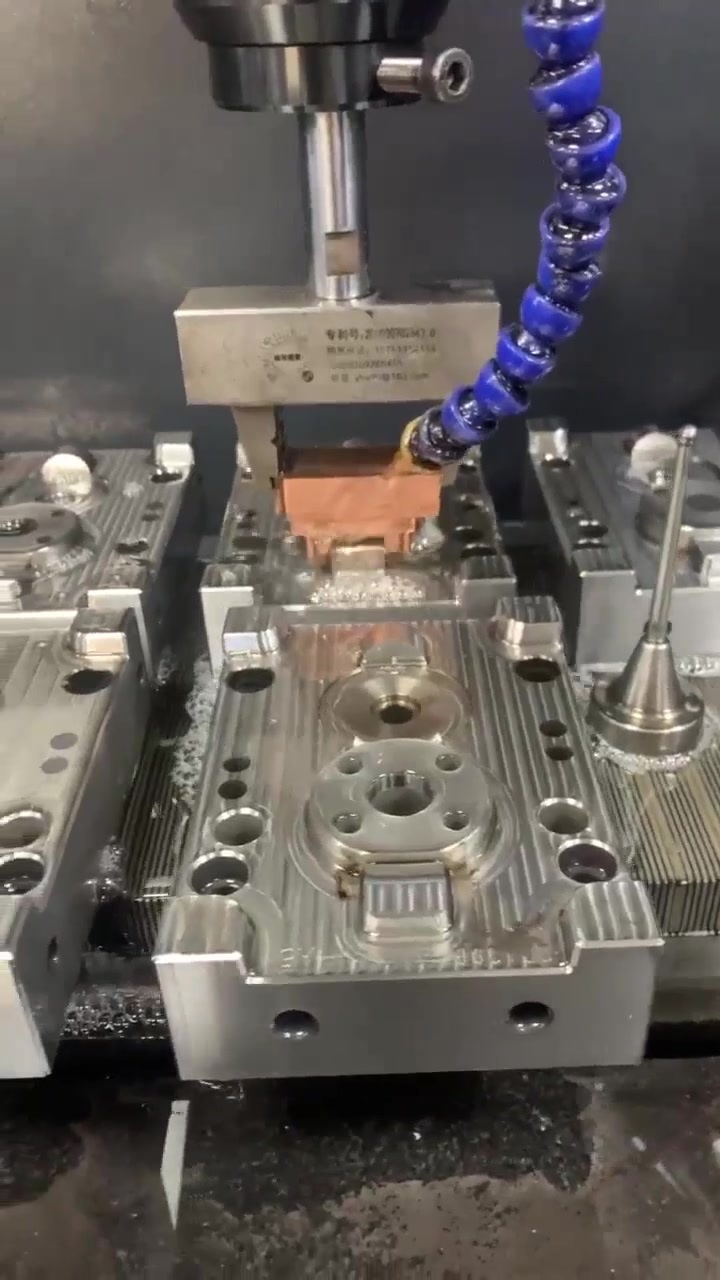

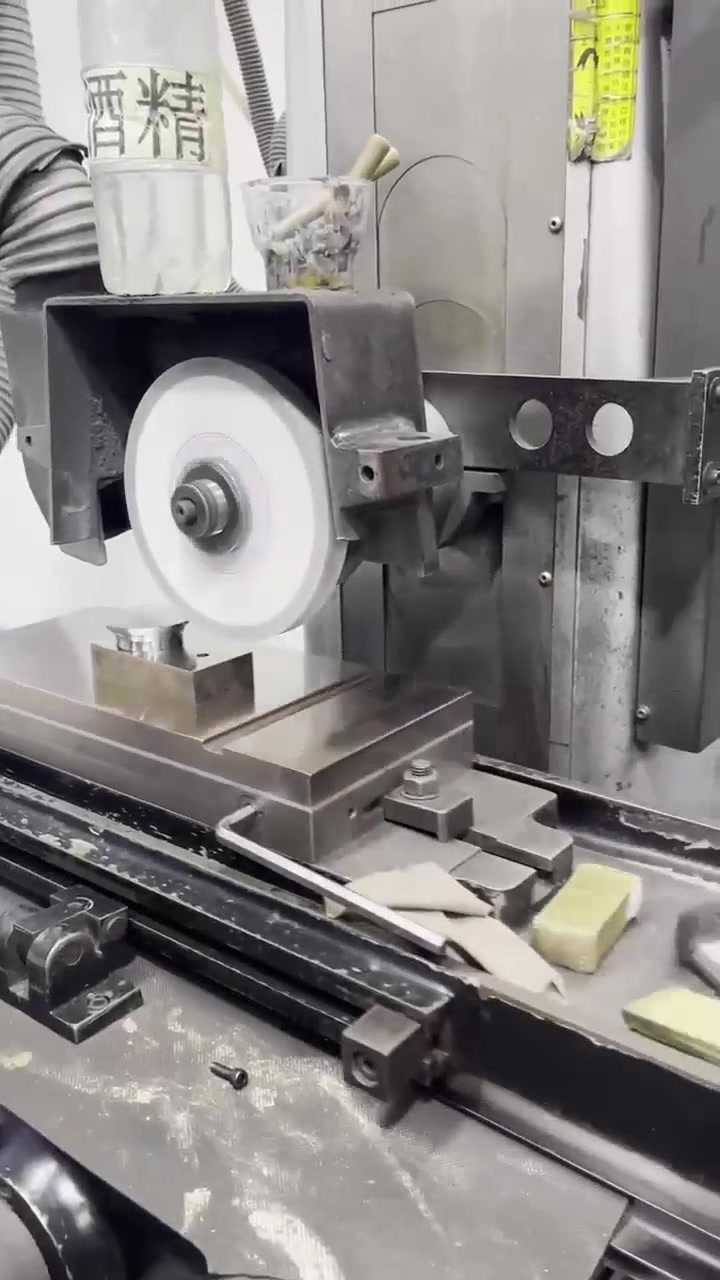

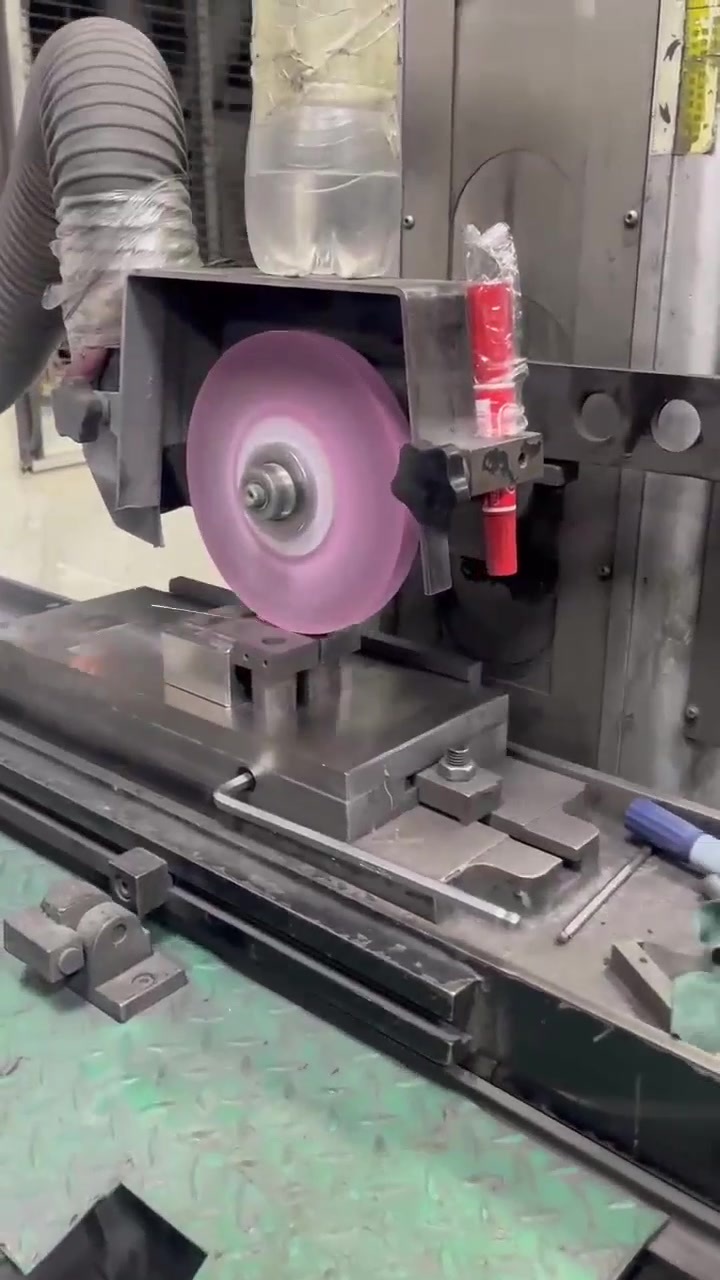

Video display

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

1

2

3

4

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.