JPZ80700HT

- Commodity name: JPZ80700HT

- Product Description

-

Product Overview

In a fast-paced tooling and production environment, every second of downtime means increased costs. Our industrial die-specific quick connects are high-performance standard parts designed for demanding die applications such as cooling water, pneumatic circuits, hydraulic system connections. They provide instant, reliable, leak-free connection and disconnection, significantly simplify tooling setup, tooling change, maintenance, and testing processes, and are key components to improve shop efficiency, system integrity, and die life

Product Features

1. Speed operation to improve efficiency:

"Plug and play, turn and lock": Innovative design allows quick single-handed connection and disconnection without tools.

2. Excellent sealing, no leakage:

Precision machined seal: use high quality nitrile rubber, fluororubber or polytetrafluoroethylene sealing ring, resistant to coolant, compressed air, hydraulic oil and common die chemical media

3. Durable, durable and reliable:

Industrial grade material: The main body is made of high-strength brass, stainless steel or engineering plastic, which is resistant to corrosion and abrasion, and can withstand frequent plug and unplug and harsh workshop environment.Product Application Scenario

1. Injection Mold, Die Casting Mold, Punch Mold:

2.Quick connection of cooling water system (inlet/outlet).

3.Connection of pneumatic ejection, core pulling, air blowing and demoulding.

4.Connection of pipeline for hydraulic system (such as large die-casting machine).

5.Mould maintenance and cleaning: Quick connect cleaning equipment and pressure test equipment.

Key words:

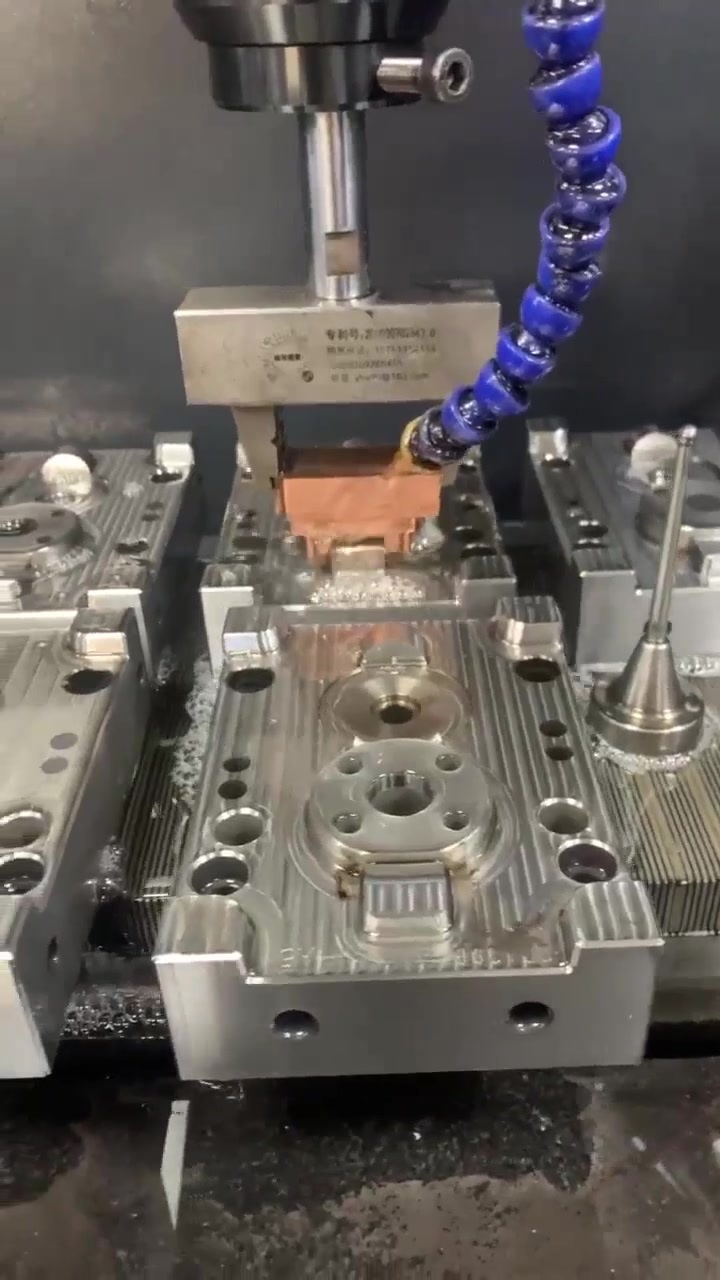

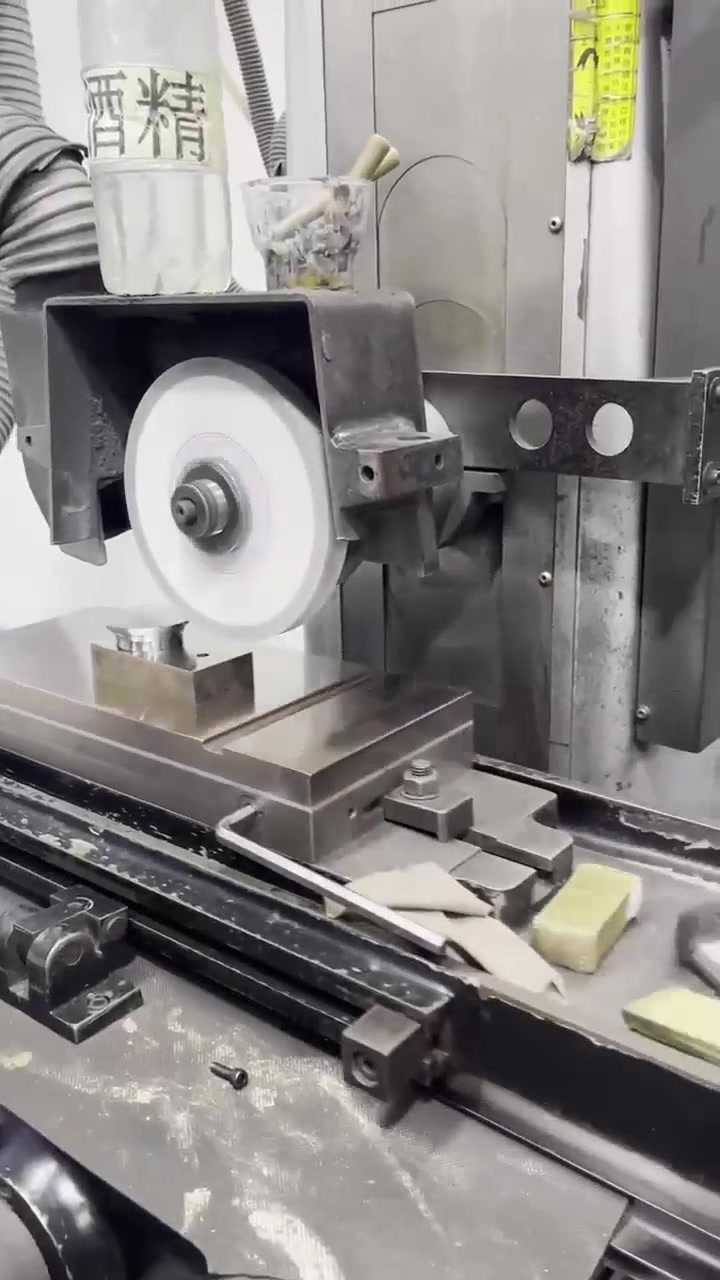

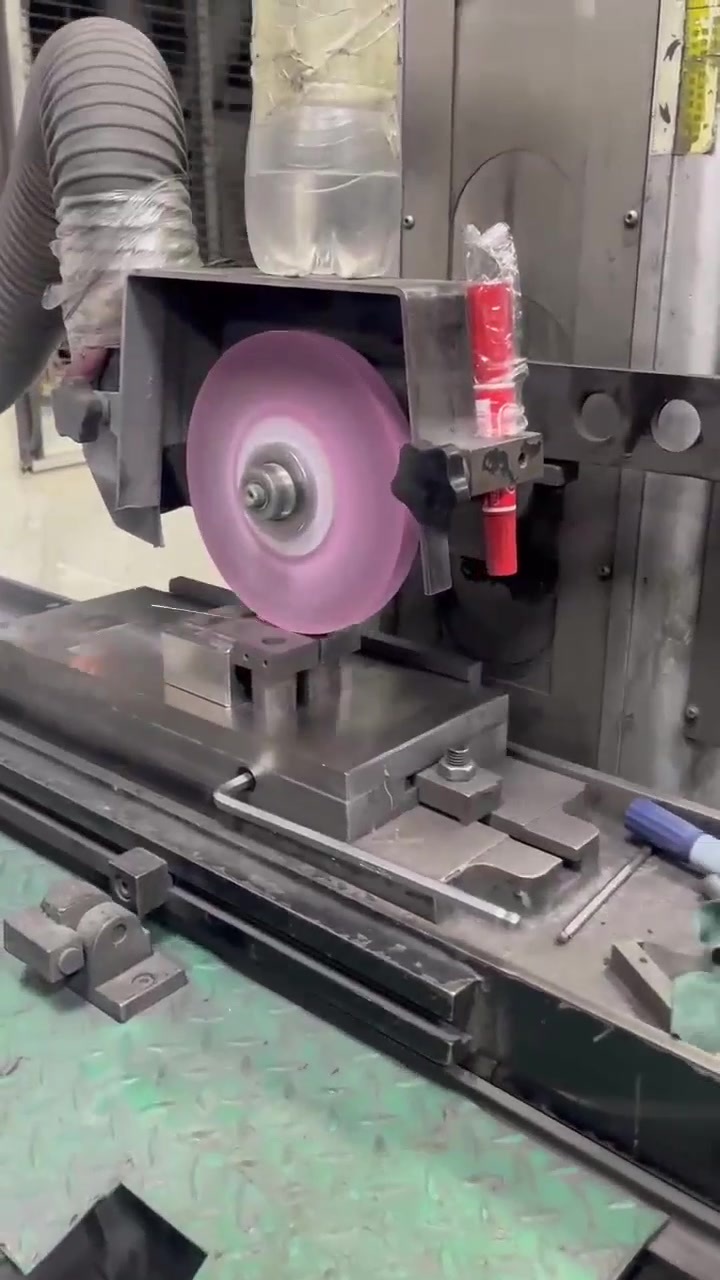

Video display

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

1

2

3

4

Related Products

Online message

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.