Core Applications of Mold Components in Electronic Device Manufacturing

Time:

2025-07-04

Core Applications of Mold Components in Electronic Device Manufacturing

📱 I. Micro-Precision Stamping: Enabling Micron-Level Accuracy

1. Connectors & Interface Components

Key Components: Carbide micro-punches (Φ0.15mm), tungsten steel guide bushes (Hardness HRA92)

Tech Innovations:

Nano-Coating: Diamond-like carbon (DLC) coating extends punch life to 5M cycles (Luxshare Precision Type-C mold)

Multi-Stage Progressive Dies: ±2μm stamping accuracy, defect rate <0.001% (Huawei 5G RF connector production)

Case: Amphenol backplane connector die achieves 120 strokes/sec (industry average: 60).

2. EMI Shields & Spring Contacts

Innovations:

Elastic reset pillars: Compensate material rebound (flatness ≤0.03mm)

Vacuum-adhesion bases: Eliminate sub-0.1mm debris (Samsung phone shield production)

🔥 II. Thermal Management Components: Engine of Cooling Revolution

1. Heat Sinks & Vapor Chambers

| Component | Technical Parameters | Benefits | Applications |

|---|---|---|---|

| Beryllium copper inserts | Thermal conductivity 210W/mK, Hardness HRB85 | Cooling time -40% | Dyson bladeless fan motors |

| 3D-printed micro-nozzles | Nozzle diameter Φ0.3mm, pitch 0.8mm | Heat transfer +70% | NVIDIA GPU vapor chamber dies |

| Nano-composite cores | Surface energy ≤15mN/m, anti-carbon-deposit | Demolding force -50% | Apple M-series chip coolers |

2. Heat Pipe Flattening

Challenge: Preventing 0.25mm copper pipe rupture during flattening

Solutions:

Progressive-diameter rollers: 8-stage compression for uniform stress

PCD (polycrystalline diamond) rollers: 2M-cycle lifespan (10× conventional steel)

📲 III. Consumer Electronics Housings: Aesthetics Meets Function

1. Metal Frames & Casings

Tech Solutions:

Nano-spiral cooling channels: Radius R0.5mm, eliminates CNC tool marks (Foxconn iPhone titanium frame: 9-sec cycle)

Gas-assisted molding: Pressure control ±0.02MPa, erases weld lines (laptop casings)

2. Glass/Sapphire Covers

Key Components:

Ceramic cores (Hardness HV2200): Mirror finish (Ra0.025μm)

Vacuum rotary stages: Positioning accuracy ±1μm (BYD Electronic Apple Watch sapphire line)

Yield Control:

Anti-static ejector pins: Prevent dust adhesion, yield →99.3%

💡 IV. Semiconductor Packaging: Nanoscale Precision

1. IGBT Module Encapsulation

Critical Components: Porous metal vacuum cores (pore size Φ0.1mm)

Innovations:

-95kPa vacuum adsorption: Gold wire offset <3μm (Infineon line yield: 99.98%)

AlN ceramic plates: Withstand 1500°C, flatness ≤1μm/100mm

2. Chiplet Heterogeneous Integration

Breakthroughs:

μBump forming inserts: Solder ball Φ40μm, pitch 60μm

IR alignment system: Placement accuracy ±0.5μm (AMD 3D V-Cache)

🔌 V. PCB Manufacturing: Ensuring High Reliability

1. FPC Micro-Drilling

Challenge: Polyimide rebound causing hole deformation

Solutions:

Tapered punches (entry angle 0.25°): Compensates 0.8μm rebound

Ultrasonic-assisted punching: 40kHz vibration, burr height ≤5μm (Avary 5G antenna module line)

2. Stencil Etching

Key Component: Ultra-hard graphite electrodes (density 1.85g/cm³)

Parameters:

Etching precision ±3μm (TSMC CoWoS packaging stencils)

Surface roughness Ra0.1μm ensures solder paste consistency

🤖 VI. Smart Mold Systems: Industry 4.0 Implementation

| Smart Component | Function | Tech Parameters | Value |

|---|---|---|---|

| Piezoelectric sensor pins | Real-time cavity pressure monitoring | Accuracy ±0.1MPa | Reduces MacBook casing defects by 90% |

| Micro-thermocouple joints | Zone-specific dynamic temperature control | Variation ±0.3℃ | Eliminates OLED panel flow marks |

| AI vision-guided pillars | Auto-compensation for thermal expansion | Correction ±0.8μm | Ensures IC substrate hole accuracy |

🚀 Technology Evolution Trends

Material Breakthroughs:

Synthetic diamond-coated punches: Hardness HV9000, 100M-cycle lifespan (lab stage)

CNT-reinforced copper: Thermal conductivity ≥550W/mK (NASA tech transfer)

Multi-Scale Manufacturing:

Hybrid laser-electrochemical machining: Enables Φ5μm micro-punches (brain-computer interface electrodes)

Quantum dot coatings: Self-healing micro-scratches (Samsung Patent KR1020240001234A)

Digital Twin Integration:

Virtual trial systems: Predict melt flow defects (Siemens Simcenter 3D)

Blockchain-tracked inserts: Full lifecycle data on-chain (Hexagon solution)

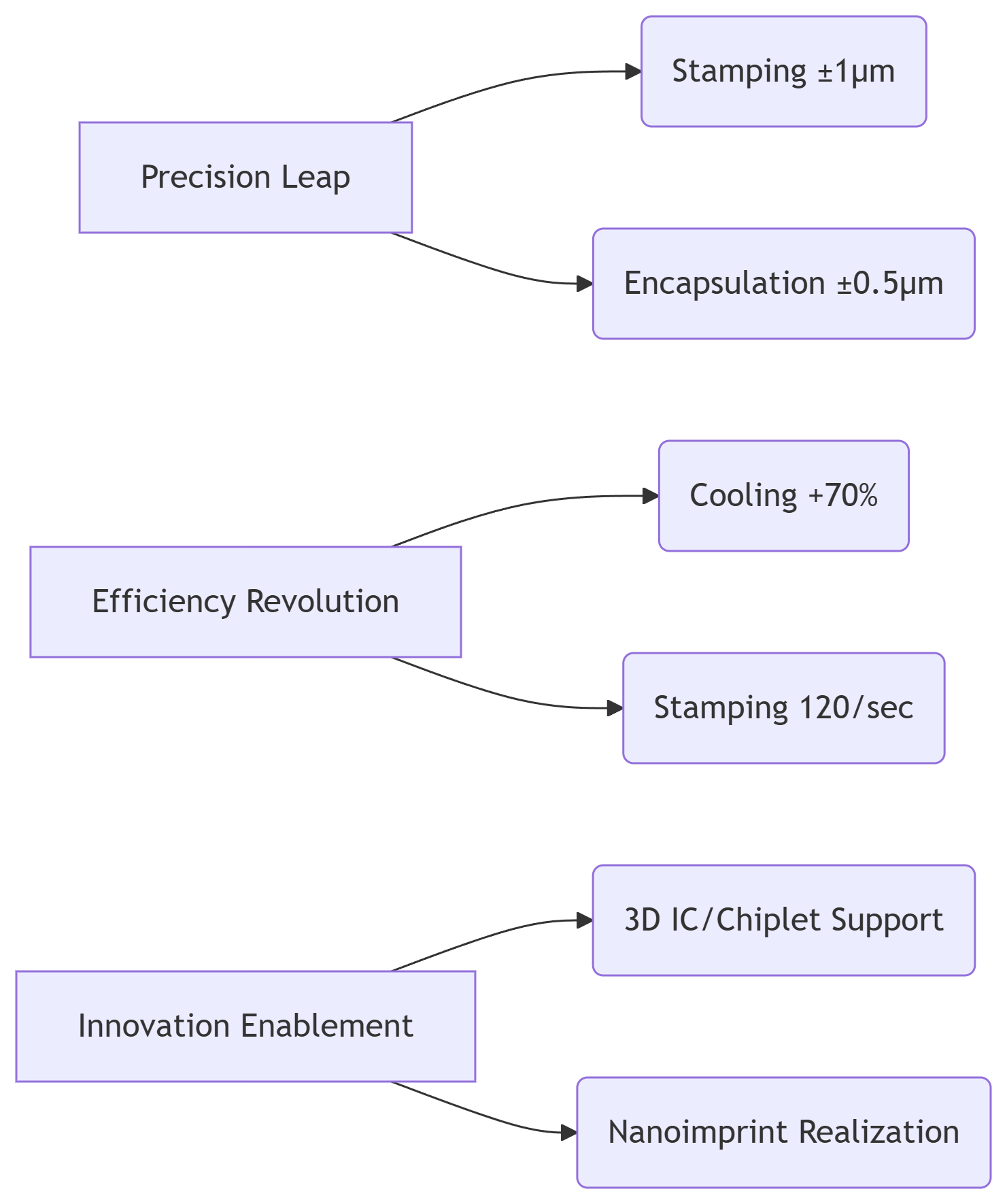

💎 Conclusion: Precision Levers in Electronics

Mold components have evolved from simple tools to integrated tech platforms:

Future Competitive Frontiers:

Sub-micron collective tolerance control in semiconductor packaging (e.g., 10k-hole consistency within 1μm)

Multi-functional integrated molds (injection + circuit embedding + optical inspection) for consumer electronics.

🔤 Glossary

FPC: Flexible Printed Circuit

IGBT: Insulated-Gate Bipolar Transistor

PCD: Polycrystalline Diamond

μBump: Micro bump (micro-solder ball)

CoWoS: Chip-on-Wafer-on-Substrate (TSMC's 2.5D/3D packaging)

Previous:

Previous: