Dongguan Jinpan Mold Parts Co., Ltd

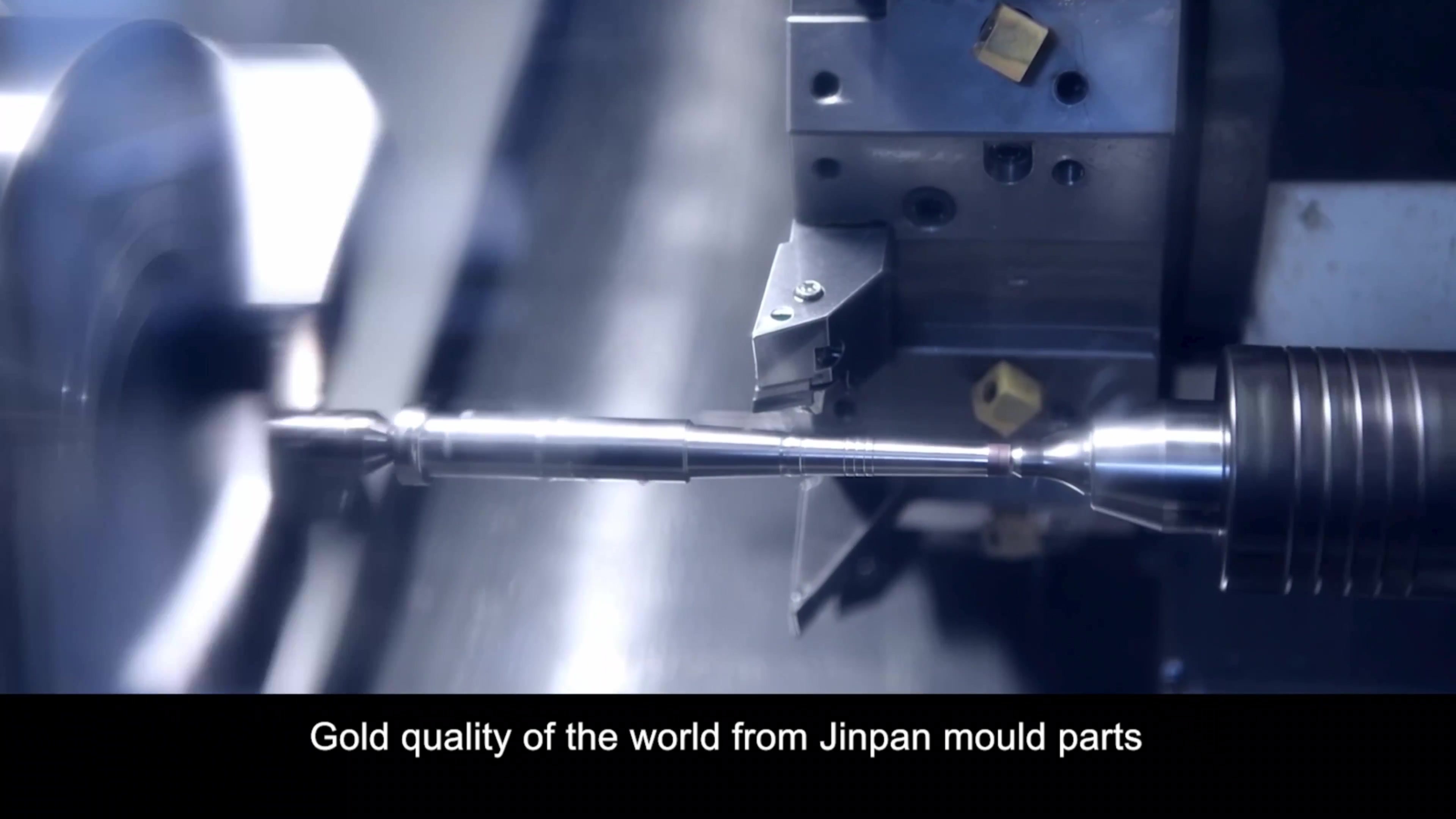

Manufactures High-End and High-Precision Mould Systems & Components

At JP, we deliver high-quality products and exceptional service to all customers, backed by our strong know-how, advanced technology, and rigorous production management. Our main product line features threaded cores, collapsible cores for cosmetics, medical components, pen core pins, gear racks, and lock clamping buckles. We also offer CNC milling & lathe machining, precision screw thread grinding, internal and external cylindrical grinding, EDM, ensuring comprehensive solutions for our clients.

Our factory covers more than 6,000 square meters

We produce more than 1,500 complete projects per year

We have more than 15 years experience in making custom mould systems & components

We help our customers to reduce the lead time of their projects by at least 15 days

We support our customers in real-time

Jinpan Five Advantages

Mold Accessories Production

The factory covers an area of more than 6,000 square meters. It helps customers produce more than 1,500 sets of mold parts every year, helping customers shorten the mold cycle by more than 15 days. It has long-term cooperation with many well-known companies such as BYD, Dongjiang, Changhong, and Han's Laser.

01

Focus On Mold Accessories Production

02

Good Quality Starts From Raw Materials

03

Create Industry-leading Products

04

Less Worry And Less Effort

05

More Punctual Delivery

News Center

Instant reports, covering global hot news, in-depth analysis, providing the latest information

Partners

Dongguan Golden Plate Mould Fittings Co., Ltd.

You Can Leave Us A Message Or Add Wechat To Contact Us Directly

“

Adhering to the concept of innovation, we are committed to continuously developing new and improved products. In order to meet the needs of application scenarios, our professional technical team continues to innovate products.

”